ISO 9001 has released new revision on Nov 2008, basically that is nothing much change on the new revision.

It still remain the main framework like ISO9001:2000 version.

We still able to obtained ISO9001:2000 verison currently if you want, however, only until 15 Nov 2009, So any new company who wish to obtained ISO 9001 certificaiton, after Nov 2009, must persuit to 2008 version.

For the existing company who already obtained ISO9001:2000 version, you have about two years time to convert to new 2008 version, the dead line is 15 Nov 2010.

ISO, 9001, ISO9001, ISO9001:2008, ISO 9001:2008 Quality Management System, ISO Procedures.

Tuesday, June 2, 2009

Friday, April 10, 2009

ISO9001:2008 Requirements Overview

Overview of ISO9001:2008 Requirements

ISO 9001 requirements can be grouped into 5 main clauses:

4.0 Quality Management Systems

5.0 Management Responsibility

6.0 Resource Management

7.0 Product Realization

8.0 Measurement, Analysis and Improvement

This exclusion does not absolve the organisation of responsibility to provide product and /or services which meets customer and regualatory requirements.

ISO 9001 require a set of document we must prepared for our people to follow and audit, the mininum requirement for doumentation are list below:

To implement this, you must have a document call "Quality Manual", inside the "Quality Manual" it must have Quality Policy and Quality Objective. Quality Mamual also need to include the Business Scope, and the linkage of each related procedures. (refer to ISO 9001:2008 clause 4.2.2 Quality Manaul)

Beside the Quality Manual, you are also require to prepare Quality Procedure, six Quality Preocedures are MUST be include, there are:

ISO 9001 requirements can be grouped into 5 main clauses:

4.0 Quality Management Systems

5.0 Management Responsibility

6.0 Resource Management

7.0 Product Realization

8.0 Measurement, Analysis and Improvement

We shall follow all the requirements stated in each clauses. However, Exclusions is given (limit to clause 7) due to nature of organisation's product, customer reuqirements, applicable requlatory requirements.

This exclusion does not absolve the organisation of responsibility to provide product and /or services which meets customer and regualatory requirements.

Documentation Requirements

ISO 9001 require a set of document we must prepared for our people to follow and audit, the mininum requirement for doumentation are list below:

- Documented statements of a Quality Policy and Quality Objectives.

- A Quality Manual.

- Documented Procedures required in this Int’l Std.

- Document required by the organization to ensure effective operation control of its processes.

To implement this, you must have a document call "Quality Manual", inside the "Quality Manual" it must have Quality Policy and Quality Objective. Quality Mamual also need to include the Business Scope, and the linkage of each related procedures. (refer to ISO 9001:2008 clause 4.2.2 Quality Manaul)

Beside the Quality Manual, you are also require to prepare Quality Procedure, six Quality Preocedures are MUST be include, there are:

- Control of Document Procedure

- Control of Quality Record Preocedure

- Control of Non-Conforming Product Procedure

- Corrective Action Procedure

- Preventive Action Procedure

- Internal Audit Procedure

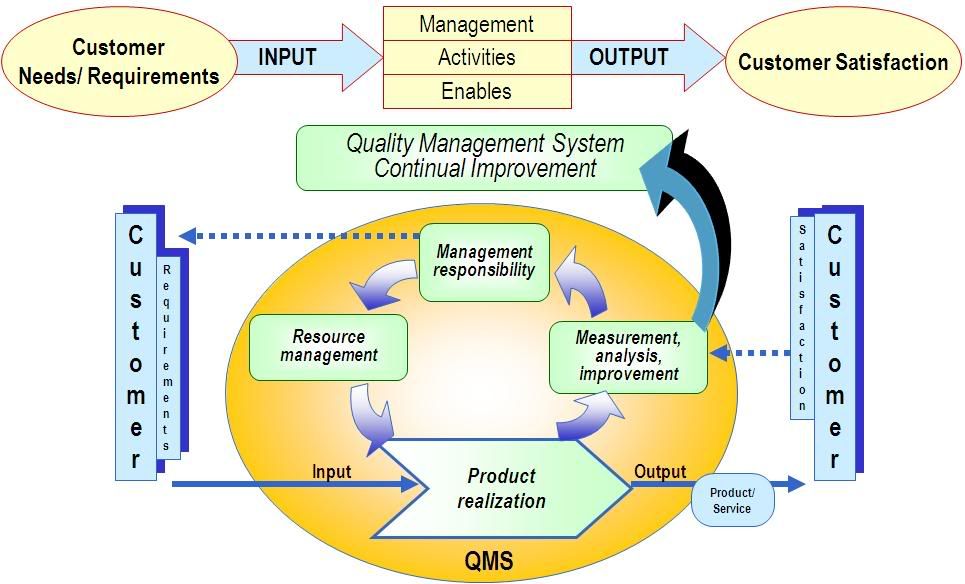

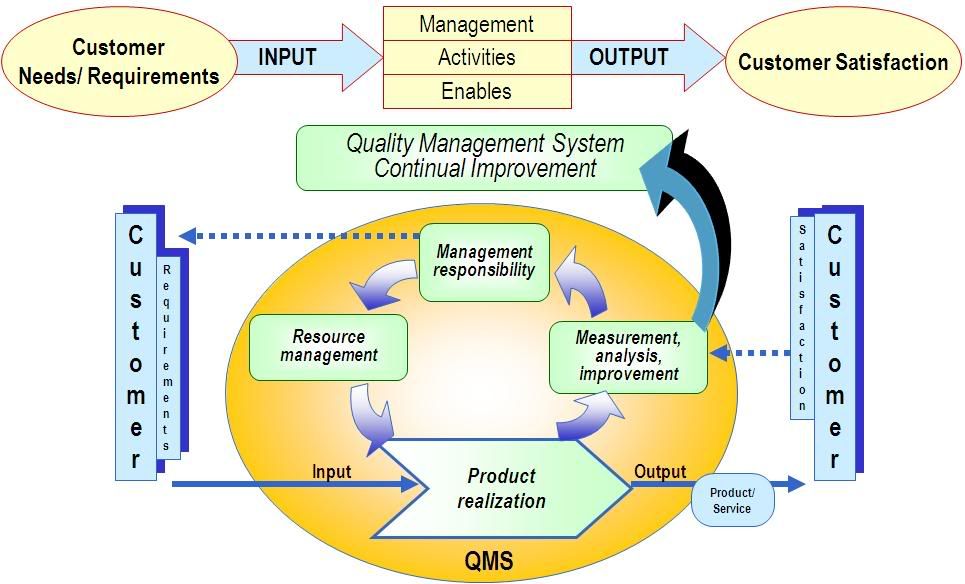

ISO 9001 Process Approach by PDCA

The ISO is promote to use Process Approach when developing, implementing and improving the effectiveness of a quality management system, to enchance customer satisfication by meeting customer reuqirements.

Action

Take actions to continually improve process performances.

Below is the model of Process-Base Quality Management System

From the graph above, we can know, our ultimate goal is to obtained Customer's Satisfication.

PDCA (Plan, Do, Check, Action) is a well known tool can be applied to all processes. PDCA can be briefly described as follows:

Plan

Established the objectives and processes necessary to deliver results in accordance with customer requirements and the organisation's policies.

Do

Implement the pcocesses.

Check

Monitor and measure processes and product against policies, objectives and requirements for the product and report the results.

Action

Take actions to continually improve process performances.

Below is the model of Process-Base Quality Management System

From the graph above, we can know, our ultimate goal is to obtained Customer's Satisfication.

Monday, April 6, 2009

Basic Understanding of ISO9001

What is ISO?

ISO stand for International Organization for Standardization and is the most established quality framework in the world. ISO is a Non-profit Organisation and established in 1947. The head office is base on Geneva, Switzerland, total over 170 member countries in the world.

ISO 9001 helps you to run your business more efficiently and effectively as well as meet your customers requirements. It also help to control company in more systamtic way and ensure continual improvement throught the corrective and preventive actions.

Why implement ISO 9001:2008?

Experience shows that business that lead in quality are no longer dependent on competing on price.

in the cusotmer's eyes, achievement of the ISO 9001 standard add value to the company and services.

It is a testimony that saves one having to prove the quality standards to deiscriminating customers.

The advantage of implemeting ISO9001:2008

- Useful objectives to measure/design the business against.

- Good opportunity to remove unncecessary paperwork.

- Forces you to look at interfaces & process.

- Helps put control in the business.

- Helps manage change.

- Reduce wastage and pproblems.

- Working to "World Class" requirements.

- Clear business vision.

- Customer satisfication

- Improve employees' motivation and competents.

ISO9000:2008 Series

In order to understand the ISO9001 further, you should know the ISO9000 standard series;

ISO 9000 Quality Management Systems: Fundaments and Vocabulary

ISO 9001 Quality Management Systems: Requirements

ISO 9004 Quality Management Systems: Guidelines for Performance Imrpovement

ISO 19011 Guidelines for Quality and/or Environemental Management systems auditing.

Only ISO 9001 Quality Management Sysems: Requirements can be used in auditing process, others are all for reference and improvement. Certificate Body (CB) are all base on the ISO9001 Quality Management Systems: Requirements to audit and certify company.

Subscribe to:

Comments (Atom)